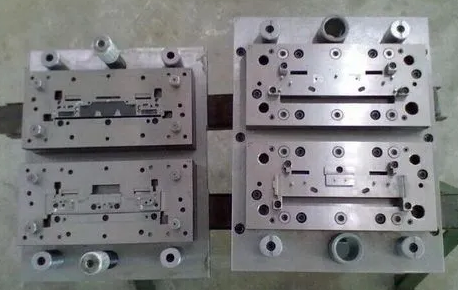

What is the single die?

The single die: the die that can only complete a stamping process in a stroke of stamping, and needs to be taken out the semi finished product from the die by manual or robotic grab, then put the semi finished product into the die of next station to continue production, untill produce the completely product. ( according to the needs of production, the process of a set of single die able to involve pierce, trim, bend, form, flange and so on) this type of die is easy to maintain, but the cost of production product is higher than progressive die .

The single die production product cost is higher than progressive die, but why factory still using the single die to produce?

The reason are: 1. because progressive die cost is more expensive than single die, according to the annual volume, if the volume is low, so will selection single die; 2. progressive die production need to using strip layout, the strip layout is composed carrier and product, according to the shape of product, if the carrier is tough to concatenate product, so have to select single die; 3. because progressive die is made up of number of steps of process, so the size of die is determined by the size of product. according to the production equipment, if the dimension of progressive die exceed bolster of press, it will be changed to single die